NyquiFix Pro

NyquiFix Pro

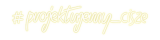

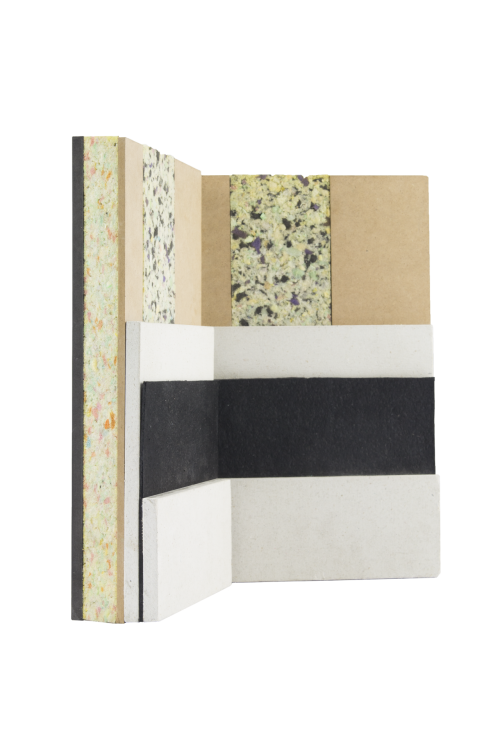

Nyquifix Pro is a multi-layer sound insulation system, intended for installation on ready-made building partitions.

Nyquifix Pro is a multi-layer sound insulation system, intended for installation on ready-made building partitions.

Frequently Asked Questions.

Acoustic panels should be adapted to the specifics of a given facility. We offer many products for acoustic insulation and adaptation, which is why our architects and acousticians will help in choosing the right solutions. In the case of more complex projects, we provide consultations based on the performed calculations, measurements and acoustic simulations.

Each Nyquista product, depending on its intended use, has the necessary documentation, such as: a technical sheet, declaration of conformity, fire classification, hygiene certificate, acoustic tests, etc. In the case of non-standard acoustic panels, we prepare technical documentation of the materials they are made of.

Yes, most Nyquista acoustic panels have the necessary documentation for installation in public facilities. Panels mounted by us on the ceiling are characterized by an appropriate fire classification, in accordance with applicable standards and legal regulations.

Nyquista acoustic panels are made of materials of the highest class of sound absorption. The exact absorption characteristics and effectiveness in a given room depends on factors such as: the type of acoustic panels, their construction, number, size or arrangement. In the case of soundproofing mats, we use closed-cell materials with a very high insulation coefficient for acoustic insulation.

We adjust the dimensions of acoustic panels to a specific project. The maximum size of one panel from the Ecoline series is 145 x 245 cm (they can be joined together). In the case of the Fiber Color series, the maximum size is 33 x 33 cm or 30 x 60 cm. Fabric Levels upholstered acoustic panels can have a size of 140 x 200 cm. NyquiSystem acoustic panels are cut from 280 x 207 cm boards.

The stretch ceilings and walls of NyquiWall and NyquiWall Mural form a uniform structure. They have no dimensional restrictions. Delicate joints of the stretched material fall according to the width of the beam (depending on the fabric used, every 140-500 cm).

Yes, as long as graphics or photos with the appropriate resolution are used. Of course, the larger the print area, the better the photo quality is required. Before starting the implementation, our employees verify whether the selected graphic is suitable for printing.

Yes, most of our acoustic panels are adapted to a given project. We like challenges, so we often design new patterns or use unusual materials. We also work with many specialists in various fields of production. If you have an interesting project or idea for an acoustic panel, we will do our best to implement it.

Due to the fact that the projects we implement usually require an individual approach and comprehensive solutions, we do not have a fixed price list. Each acoustic project is priced individually. The price of the products depends on the quantity, type and complexity of the project.

The minimum order depends on the type of acoustic panels. Usually it is 10 m2.

Acoustics is a field that covers many issues, which is why we approach it comprehensively. The projects we implement require supervision of the entire process. Hence, we deal with the design, acoustic measurements, production of acoustic panels and their distribution.

Yes, we employ qualified teams that specialize in the installation of insulation and acoustic adaptation. Thanks to this, we take responsibility for the correct operation of our solutions. If the acoustic panels are installed by the customer, we provide the necessary instructions. On request, we also supervise the supported project implementation.

Brochures and catalog cards of most acoustic panels can be downloaded from our website - main menu, "download" tab or on product subpages. If there is something you cannot find on the website, please contact us and we will send you the necessary materials.

site map

Office / Showroom

ul. Górnośląska 1

00-443 Warszawa

Production / Warehouse

ul. Promienna 25

05-074 Długa Kościelna

Data for invoices

NYQUISTA HERSE sp. Komandytowa.

ul. Sobieskiego 153

05-070 Sulejówek

NIP: 822-236-26-24

REGON: 368233466

POLISH COMPANY

POLISH CAPITAL